Practice makes Progress

Practice makes progress is a great motto to live by. Here at Compass, we always strive to better our customer experience and company efficiency as well as our impact on the environment. We aim to think outside the box, to see if there is a greener way of creating phenomenal projects such as gates, fences, railings and stairs.or decades, we have been utilizing material with up to 97% recycled content, and using eco friendly powder coat finish that is 99.99% reclaimable and emits 0 VOC’s into the atmosphere! Check out who we are and what we stand for at this video!

In 2021, we took it upon ourselves to delve even deeper into our internal processes such as client interaction and project creation.

We revised our e-mail dialogue with clients for project developments. This allows us to have more client interaction during the pre-project design, review, and budget to reduce travel time and expenses. This also cut back on gas reducing fossil fuels consumption.

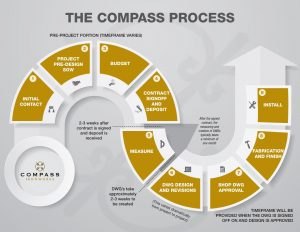

Additionally, we created a document that clearly outlines our process, step-by-step for clients. Clients have found this to be an eye-opener, as they now know all of what has to be accomplished before the contract can be signed off. Next comes all the steps to measure and design. Furthermore, clients are able to see that the time-frame for completion begins once our shop design approval has been granted. Want a peek into more of our process? Look here on our website for more details!

Another huge step to make progress was to evaluate our fabrication process. To improve in this area we now utilize sigmund tables. These are welding tables that have precise fixtures, holes, and grid lines all across the table and the sides. This makes it quite simple to do an iron railing layout. If we need a longer table, like we use for driveway gate layouts, then we can simply fasten two 4X8 tables together for an 8X8 surface. On one hand, using the tables and fixtures reminds me of a little boy playing with legos. Only now, it is a grown man, creating a beautiful iron project. The guys in the shop definitely have more fun than working with traditional flat welding tables too. So the day goes faster, they have more fun, and get more done. What a great way to make progress!