No project too big, no idea too grand

Craftsmanship

Our iron railings and staircases are more than just functional—they're works of art. Each piece is meticulously crafted by Pennsylvania Dutch artisans, combining traditional techniques with modern precision. From intricate scrollwork to clean, contemporary lines, we ensure every design reflects unparalleled attention to detail and quality.

Durability

We use only the highest-quality wrought iron and apply advanced, weather-resistant finishes to ensure your railings or staircase withstand the test of time. Designed to endure harsh weather conditions, resist rust, and maintain its structural integrity, our products are an investment in long-term durability and peace of mind.

Customization

No two properties are alike, and your railings or staircase should reflect your unique vision. Whether you prefer sleek modern aesthetics, ornate traditional details, or something entirely unique, we offer a wide range of styles, patterns, and finishes to bring your vision to life. Choose from powder-coated finishes, decorative accents, and custom dimensions to complement your property perfectly.

Functionality

Our railings and staircases don’t just look stunning—they’re designed to keep your property secure and require minimal upkeep. With advanced locking mechanisms, sturdy construction, and finishes that resist wear and tear, you can enjoy a perfect balance of beauty and practicality. Spend less time on maintenance and more time enjoying your enhanced property.

Ready to Elevate Your Property?

For more information about Compass Ironworks or to schedule a no-obligation consultation, please call us at (717) 442-4500 or fill out our contact form below.

There has been a significant increase in demand for our caliber of quality, craftsmanship, and unique product offerings. Contact our team today to get ahead of the rush and secure your next project with our team.

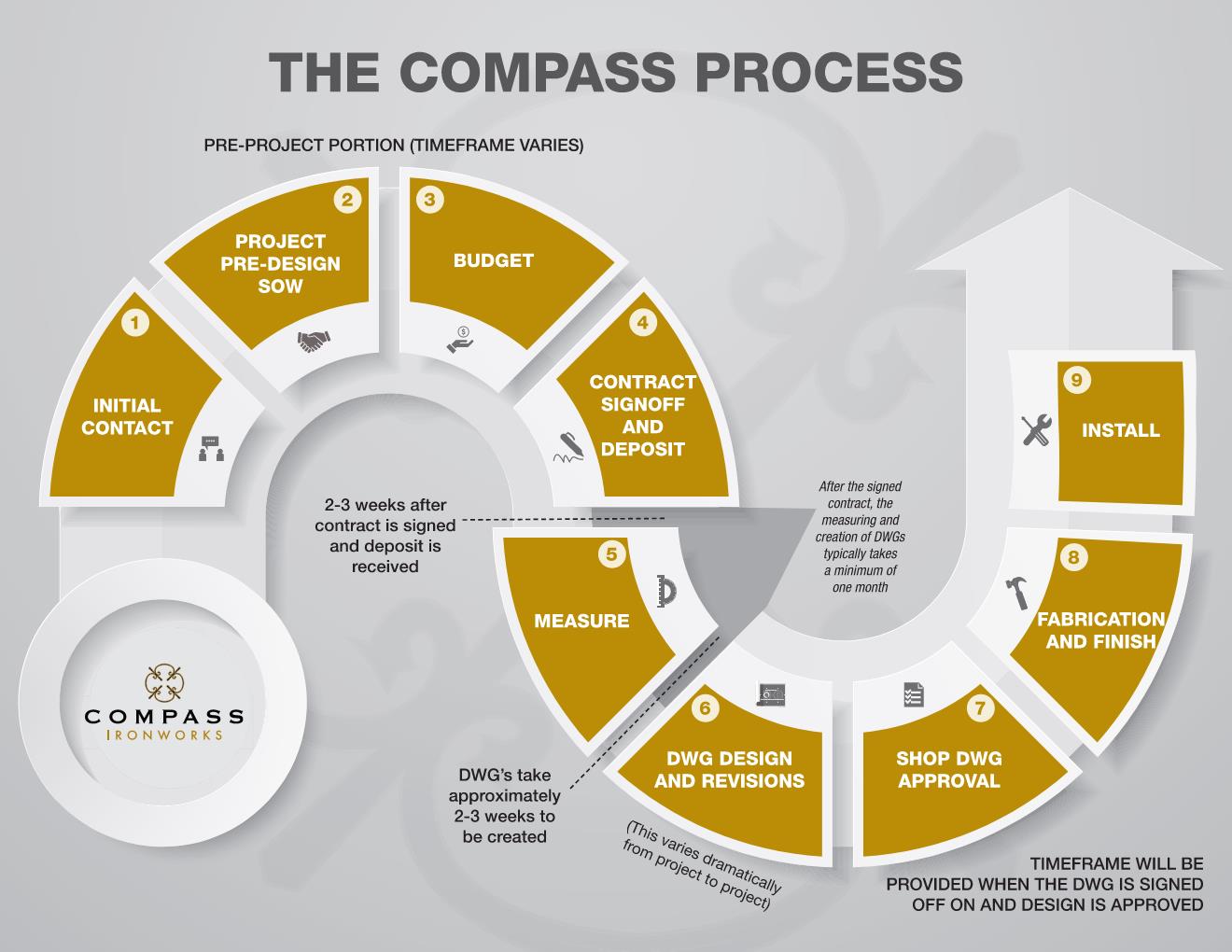

Our Process

Step 1: Initial Contact

Initial communication about your project, during which we discuss your vision and utilize our extensive design guides.

Step 2: Project Pre-Design Scope of Work (SOW):

Collection of all the details regarding your project and conversations about value engineering. During this step, we will need plans, photos of designs, photos of the area, and/or a sketch of the project in mind.

Step 3: Budget

After collecting all information pertinent to your project, we will provide you with a budget based on a specific design. Once you approve the design and budget, a formal proposal is created.

Step 4: Contract Sign-Off & Deposit

At this point, a signature of approval on the formal proposal & deposit (typically 50%) will be needed to move forward.

Step 5: Measure

Once we have your signature and deposit, we can establish a measure timeline. During this step, we will travel to the project location and take exact measurements of the area.

Step 6: DWG Design & Revisions

Next, the entire project will be designed in CAD to create an exact 2D presentation of your project.

Step 7: Shop DWG Approval

After approval, a physicaly signature is required on all drawings to confirm they have been reviewed. Once this is complete, a commitment date will be provided.

Step 8: Fabrication & Finish

During this step, all of your project's fabrication will be completed. This custom, in-house work includes sandblasting, priming, and finishing.

Step 9: Install

Once fabrication is complete, your project will be expertly installed by our experienced and highly-skilled team.

Got Questions? We've Got Answers.

Typically, all interior work is iron. For the exterior, aircraft-grade aluminum is predominant, especially at the shore. We also work with bronze, brass, stainless steel, and other exotic metals.

Check out our design guides for additional project inspiration.