Where Durability Meets Perfection

Superior Finish to Resist Corrosion and Uplift Your Item’s Appearance

Our attention to detail and expertise brought to your metal products!

Applications

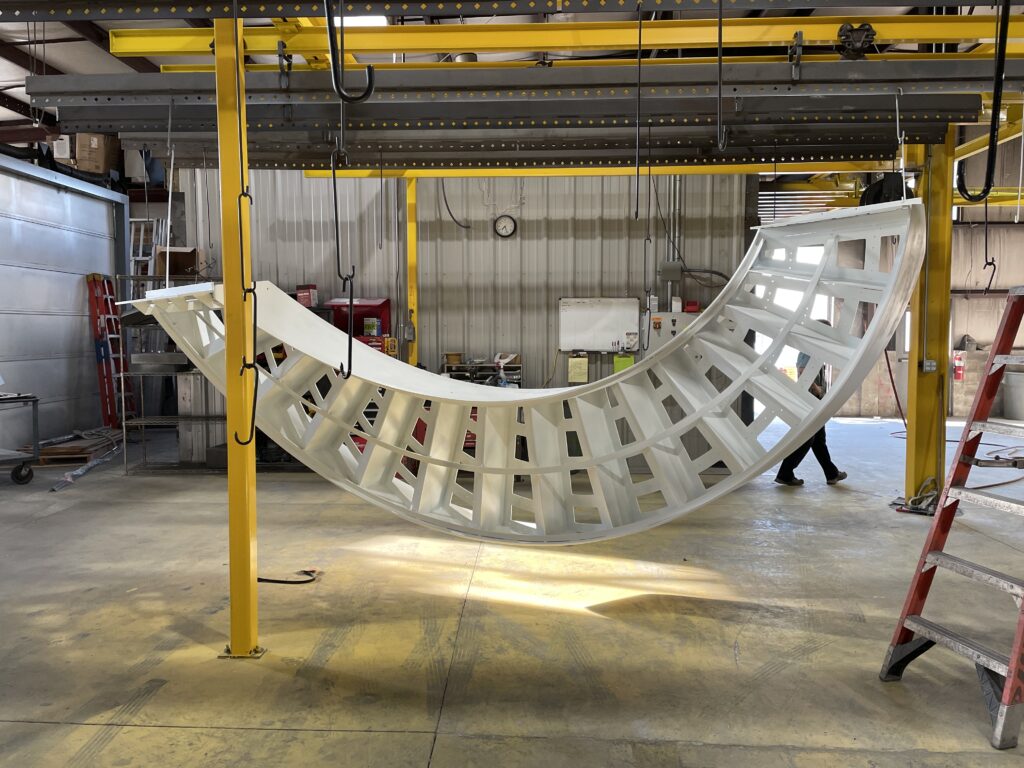

At Compass Iron Works, we pride ourselves on using traditional techniques with modern precision to elevate iron products to last a lifetime. Our Pennsylvania Dutch artisans use electrostatic applications to coat the large and/or custom metal items that no other powder coater wants to touch. We use a large 20’x10’x9’ propane convection oven to cure the product, giving you a beautiful piece within a quick timeframe. Our powder coating services typically take a week to complete.

Durability

Our powder coating services enhance the durability of the high-quality metal products we create. Less prone to wear and tear, powder coatings are applied with superior adhesion to make it difficult for moisture and rust to reach the metal. Powder coatings provide a layer of protection to your products, helping them resist weather elements and corrosion. Our durable finishes withstand even the harshest of environmental conditions.

Customization

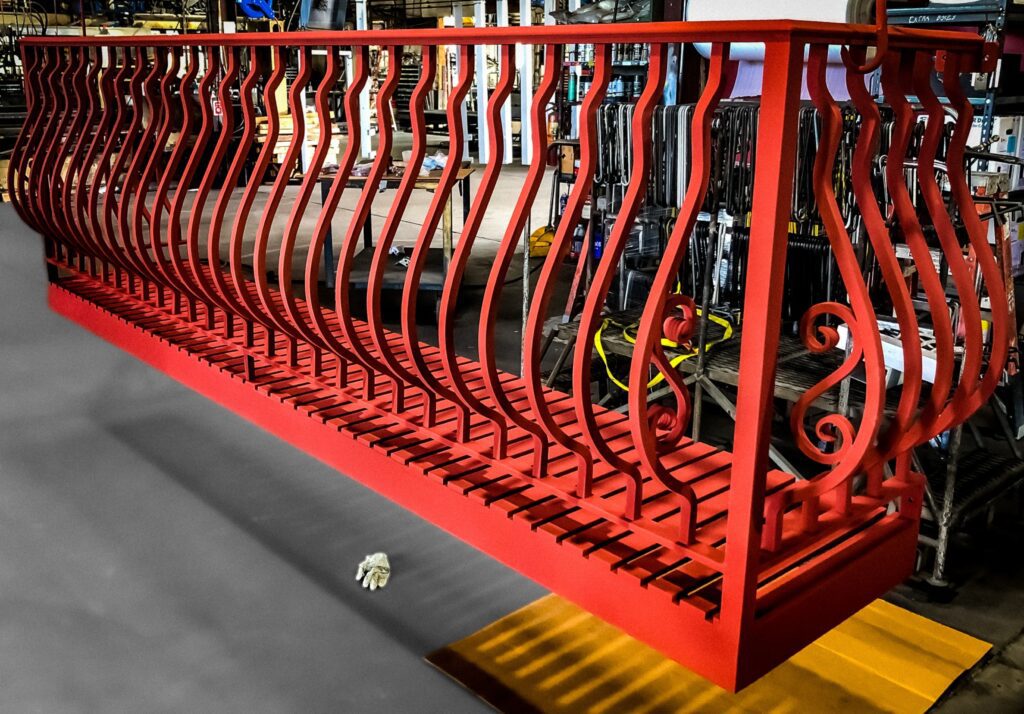

Your metalwork should reflect exactly what you want. That’s why we offer many custom coating options to bring your preferences to life. We have many colors in stock, with both gloss and matte finishes. We also offer custom colors and finishes to give your item the look you desire!

Sustainability

Powder coating is more sustainable than using paint. Paint is more expensive, less durable, and contains volatile organic compounds (VOCs). Powder coating is cost-effective, highly durable, and emits less carbon dioxide and VOCs than paint does. Our powder coating services do not release hazardous air pollutants and require less waste disposal.

Our Process

Our Powder Coating Process

Step 1

Have a conversation with one of our coating experts, and decide what needs to be done. Our large batch system can coat bulky pieces up to 20’x10’x9’.

Step 2

We blast the product to remove any dirt, oil, grease, or mill scale, which provides a physical etch to the product to increase adhesion.

Step 3

The product is blown off to ensure all loose partials are removed from the surface. For products that will be in harsh environments like the shore, we provide a three-stage wash process to ensure maximum powder adhesion.

Step 4

The product is preheated and sprayed with a primer and resilient top coat color of your choice.

Step 5

The entire product is then baked in a dedicated propane convention oven at 390° Fahrenheit for 15 minutes to completely cure the powder coat.

Step 6

Once finished, we will contact you to let you know that it is ready for pickup! We have a quick turnaround for these projects, they typically take one week from initial drop-off to pickup.

Consultation Form

Ready to Enhance Your Metal Projects?

For more information about Compass Ironworks Powder Coat Services or to schedule a no-obligation consultation, please call us at (717) 442-4500 or fill out our contact form below.

"*" indicates required fields

How We Work

What Sets Us Apart?

Environmentally-Friendly

Quick Project Turnaround

Dedicated Project Managers

Competitive Pricing

FAQ

Got Questions?

We’ve Got Answers.

We provide powder coating services to any client, not just for ironwork that we have fabricated ourselves. If you have ironwork that needs to be powder-coated, contact us to schedule a no-obligation consultation.

We typically work with clients that have custom fabrication shops, clients that have large items like trailers, gates, and furniture that need powder coatings, and clients that need high-quality finishes for their wrought ironwork.

We offer many colors with glossy and matte finishes, including standard colors like black, white, and brown. We can also create custom colors, any color can be custom matched to your needs.

Our process takes about a week to complete, from the initial parts drop off to when you pick up the completed project.

Powder coating is better than paint because it is more sustainable, durable, and cost-effective. The powder coat finish is smoother than paint, and the superior adhesion we use makes it hard for moisture and rust to get to the iron materials, making powder coating less prone to wear than paint.